Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Applicable Industries: Slaughtering Waste Processing Industry

After Warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Condition: New

Brand Name: Lysf

Type: Chicken & Animal Meal Machine

Warranty: 1 Year

Key Selling Points: High Productivity

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Place Of Origin: Zhejiang, China

Voltage: 220-450v

Weight: 8000 Kg

Certification: Iso Sgs Ce

Packaging: IN 40HQ CONTAINERS

Supply Ability: 3 Set/Sets per Month

Port: Ningbo China

Payment Type: L/C,D/P,T/T

Incoterm: FOB,CFR,CIF,EXW

HOT SALES CHICKEN MEAL MACHINE/SLAUGHTERING WASTE PROCESSING PLANT/ CHICKEN WASTE RENDERING EQUIPMENT

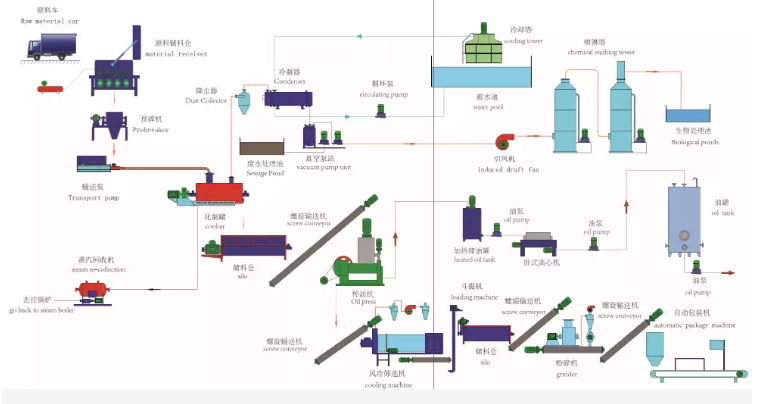

The whole line were consists of material buffer bin, conveyor, cooker, dryer, grinding, cooling, packing and odor treatment system.

1.poultry waste reception section

1, The material silo

Function: for the reception and storage of poultry waste,dead animal.

2, The middle is pre-crushing machine

Function:for chopping of whole animal carcasses and large pieces with aim of 50mm size pieces(easily transported)

3, The botton is a material pump.

Function:transport the material to cooker.

2. Cooker and dryer section

Fuction: Waste of raw material (feathers,animal fur,sick livestock,animal carcasses)through tghe process of high temperature and pressure to achieve the effect of sterilization and break down.

Features:Big capacity of each batch,the efficiency of sterilization is completely and safe. It has the fuction of break, cook, sterilization and drying.

Final products:

Drying method of disposal method has the following features, automatic control, processing quickly, clean thoroughly to germs and environmental science processing, the production of 100% without peculiar smell, does not produce secondary pollution, processing the finished product, can bring good social benefits, is, in the world, the most recognized treatment.

Function: the principle of abandonment (feathers, animal fur, diseased animal and animal carcasses) is achieved through high temperature and high pressure technology to achieve the effect of sterilization and sterilization.

Characteristics: single batch processing is large, the sterilization effect is safe and thorough, and integrates crushing, sterilization, sterilization and drying.

Structure: 1. Jacket structure, filled with steam.

2. The stirring shaft is inflated to increase the heat exchange area and improve the production efficiency.

3. Integral steel structure bracket, can change the installation position arbitrarily.

4. It is convenient to operate with the bump type structure.

5. The external insulation is made of stainless steel plate, which can enhance the anti-corrosion ability, prolong the service life and the appearance is beautiful.

6.Using the steam recovery system, the steam is recycled to the boiler to reduce energy consumption and save water.

Process Flow:

Crusher ----> Cooker ----> Dryer ----> Defatting ----> Cooling ----> Milling ----> Packing

After cleaning the feather dust, it is put into a hydrolyzed tank, hydrolyzed at high temperature and high pressure, then dried, cooled, crushed and packaged into finished products.

The hydrolyzed feather powder processing technology is relatively advanced, its outstanding characteristic is thoroughly feather Angle protein stability of spatial structure, so that it becomes soluble protein of the livestock and poultry can absorb, digest rate above 75%.Suitable for fishmeal supplement, added to fish meal, good sense, good fluidity, can improve protein reduce cost, the key is not to affect feeding effect.

Notes:

We can design a turnkey production line for our customers,the line including many machines,customer also can choose the one they need depend on their production and the founds,so no matter what requriements you have,we will try our best to with you

Pre-sale Service:

Your inquiry related to equipment or price will be replied within 24 hours.

Well-trained and experienced staff will answer all your inquiries in English of course.

We accept OEM&ODM projects.

We have strong R&D team here to help.

Your business relationship will be confidentional to any third party

After-sale Service:

1 year warranty period, please don't hesitate to contact us if you have any question with the equipment

Product Categories : Meat And Bones Meal Production Line > Meat Meal Drying

Mr. Michel

Tel:

86-580-2054750

Fax:

86-580-8091606

E-mail:

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.